System architecture

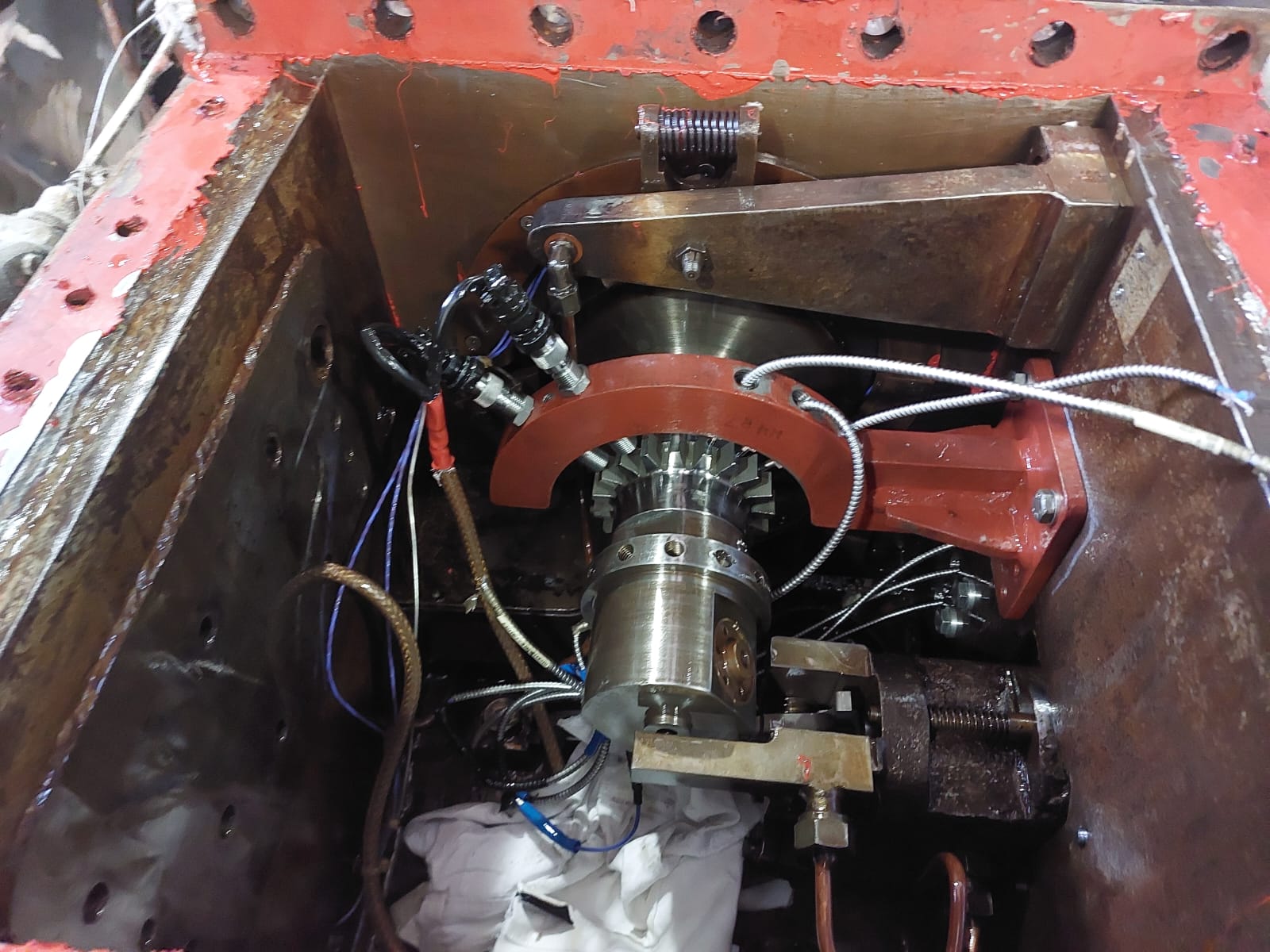

In this steam turbine application, 2 sensors were installed for speed control and 3 sensors for overspeed protection.

Some details on the redundancy of the system:

- Turbine control. The sensors are read in through a single CPU. Therefore, the two sensors are operated in 1-in-2 logic, i.e. in the event of a fault, and therefore with only one sensor in operation, the turbine continues to be regulated. In this case, the speed controller selected is a Woodward Flex500.

- Protection. The overspeed system consists of 3 independent modules, each with a redundant power supply and 1 independent speed measurement. In this case the degree of redundancy on the measurement is threefold and we speak of logic 2 out of 3, i.e. the instrument only commands a stop when at least two sensors detect a high level, but not if only one detects it. The overspeed system is assigned to the Woodward ProTech GII.

Event analysis

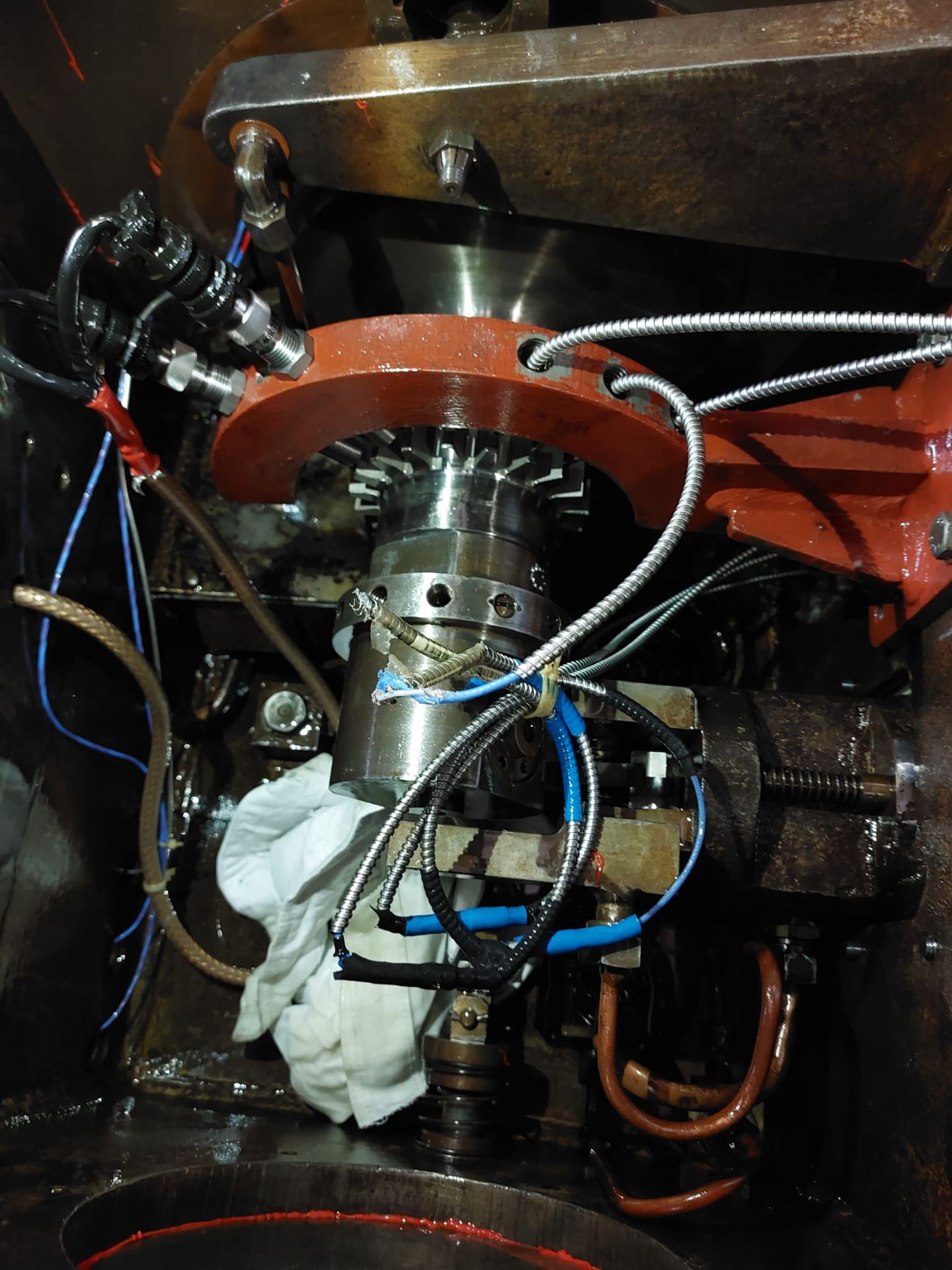

Following maintenance, the sensor connectors, which were loose in the rotating case, were sheared off by the phonic wheel itself at the first turbine rotations.

The control system, as well as the overspeed device, immediately recognized the lack of measurement and commanded a turbine stop.

When the sensor box was opened, the fault was evident, and the sensor connectors were replaced.

Once the normal operating condition was restored, it was possible to start the machine.

Safety logic

In this project, the following safeties were active on the machine:

- overspeed. Constant monitoring, in each machine sequence, of the turbine speed against the set overspeed threshold.

- wire break detection. A dedicated speed measuring circuit ensures an electrical continuity check on the measuring circuit for passive speed sensors such as magnetic/variable reluctant sensors.

- loss of speed. In any operating condition, a drop in the speed measurement below a minimum speed threshold causes the immediate stop.

- Speed discrepancy. Speed measurement discrepancy between the measurement sampled by two sensors causes immediate failure of the measurement loop that transmits the lower measurement, thus ensuring a measurement based on the highest signal.

- Over-acceleration. The system triggers an immediate turbine shutdown to anticipate the overspeed condition based on measured acceleration.

Woodward has distinguished itself over the

years for high standards in the control of turbomachinery. The control and protection features described

in this article are available on the Woodward control catalogues.

To learn more about turbomachinery protection and control techniques, contact us or request a course from one of our specialists.